Kyosho’s SC6 is the latest competition kit to be offered in the current Ultima series that includes the RB6 buggy and RT6 stadium truck. After taking a quick look through the box and browsing through the instruction manual, I was eager to build this very high-quality short-course truck for review in the November issue of RC Car Action. Let’s get started.

Kyosho breaks down the SC6 build into sections that consist of front end, the transmission/rear end and the shocks.

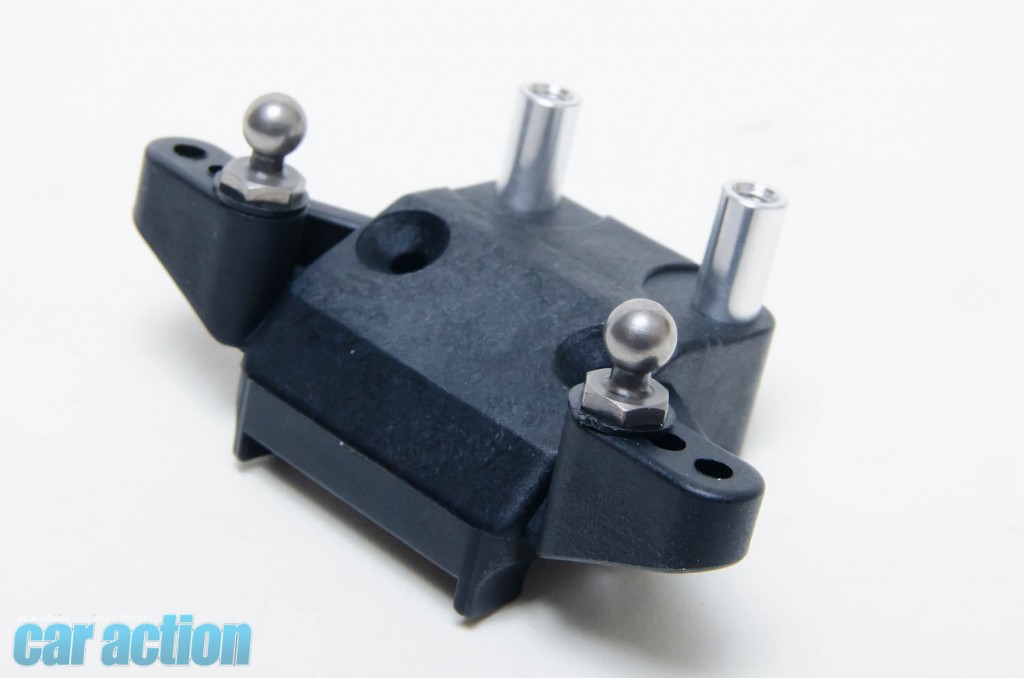

The first thing you build on the SC6 is the front bulkhead. Aluminum steering post are inserted through the bottom and ball studs are installed into the inner most hole with a 1mm roll center washer to raise the ball.

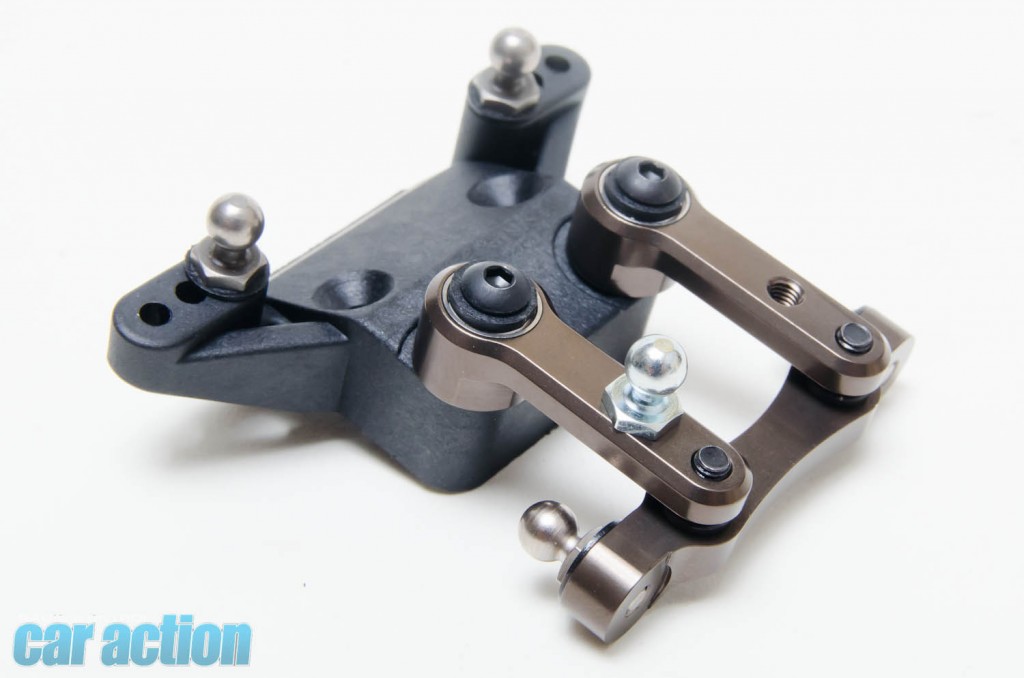

The aluminum bellcrank pieces install onto the previously installed aluminum steering posts. The bellcranks ride on ball bearings for ultra precise steering action.

Step 5 has you install mounting hardware and the spring loaded servo saver to the servo. The servo saver makes the SC6 forgiving to drive and is good for outdoor loose conditions. For an indoor, higher traction clay track, you might want to install a solid servo horn for a more direct feel.

The front upper plate mounts right above the steering assembly to protect it while making the front end flex free.

Step 11 in the manual has you put together the steering knuckle assembly. Here side by side is a incomplete and completely assembled unit. A hinge pin insert let you widen or narrow width of the front end.

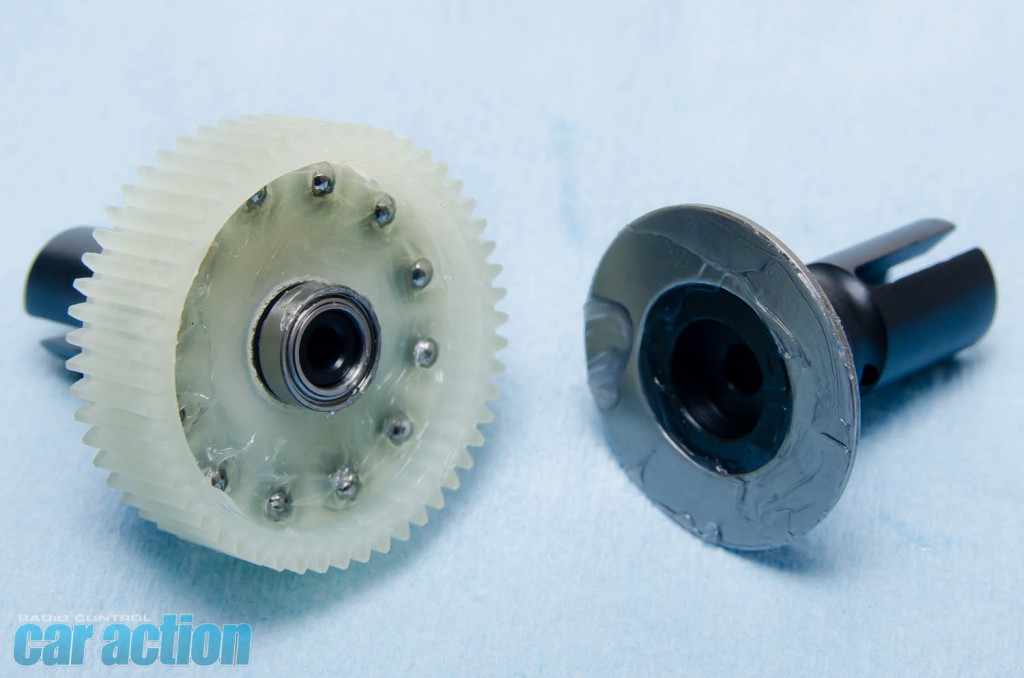

Twelve hardened steel balls are used in the differential. Tough steel outdrives are used to handle monster modified motor power.

The use of an aluminum main gear shaft helps to reduce rotating mass in the SC6 tranny. Five screws hold the transmission case together. A full set of Teflon shielded ball bearings keep the tranny spinning super free.

The steel universals come preassembled from the factory, which saves some build time. I put a small drop of oil to lubricate the joint.

These are all the parts that complete the rear hub assembly. One together, they are tidy units that are easily removed from the SC6 for adjustment or maintenance.

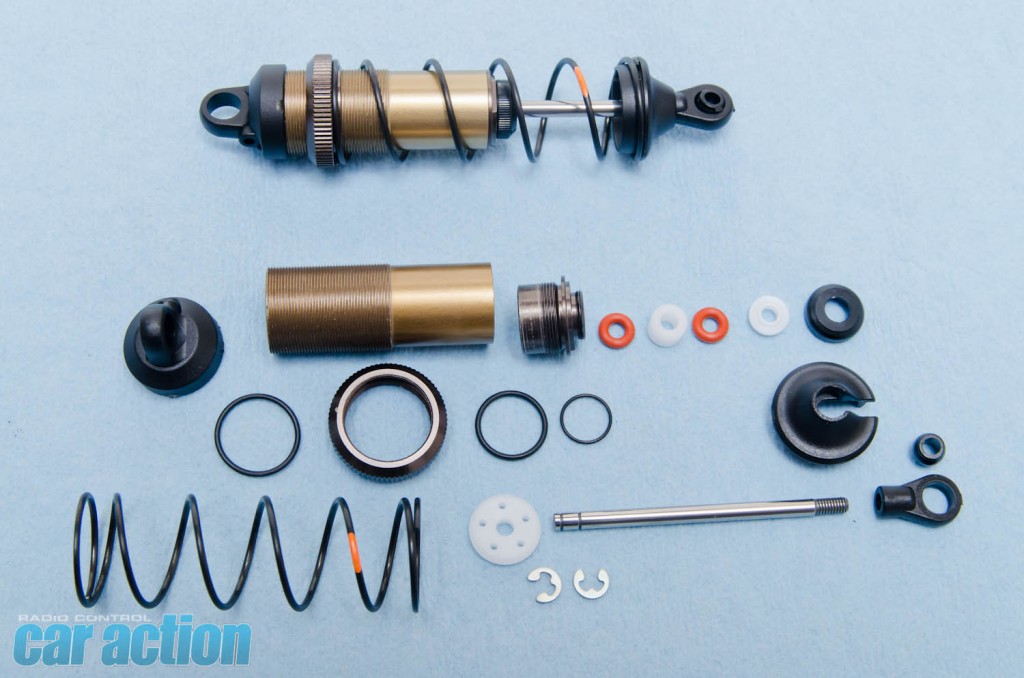

The messiest part of the build was next; building the shocks. Standard two o-ring sealing is used on the shock bottom. The plastic top shock cap has a bleeder screw to aid in the bleeding process once you have filled the shock up with oil. Here are all the parts that make the SC6 shocks and a complete one.

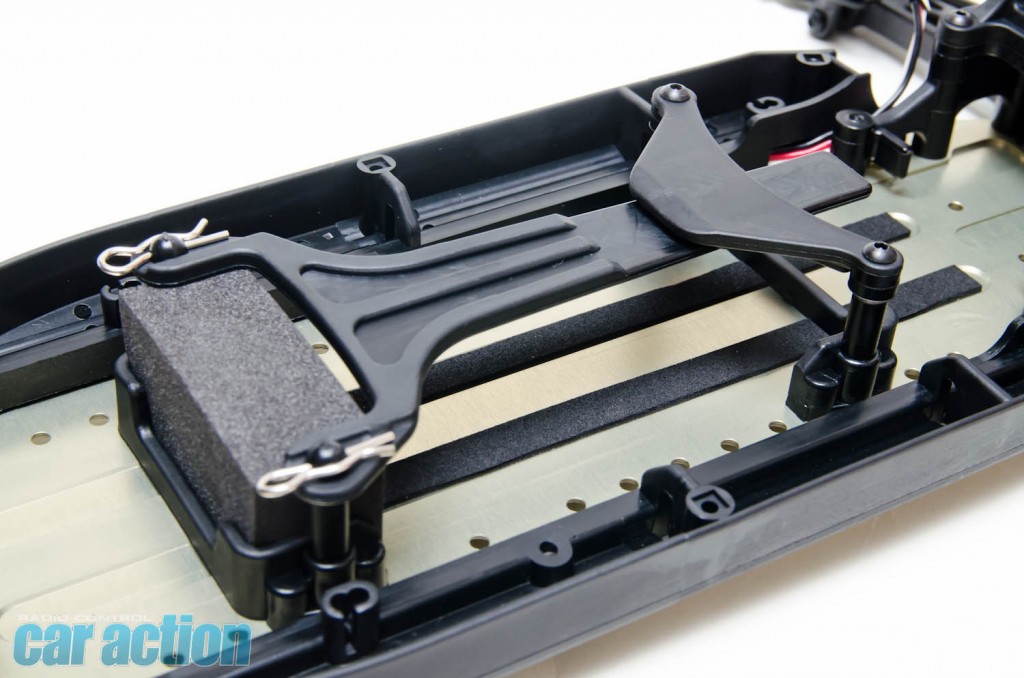

The battery mounts are adjustable to accept any sized battery. The battery strap is secured in place with two metal clips.

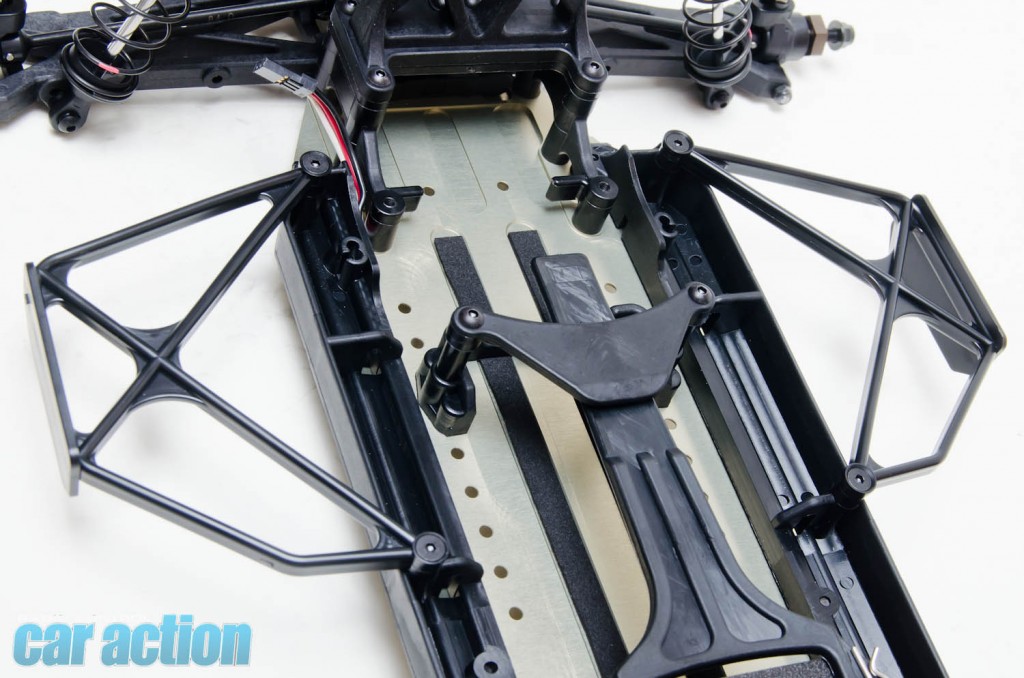

The side guards install next that will help protect the SC6 from side impacts. There is enough surface area on the end of the guards to stick on some Velcro.

The SC6 is pretty much complete at this point and ready to accept running gear, wheels/tires and body.

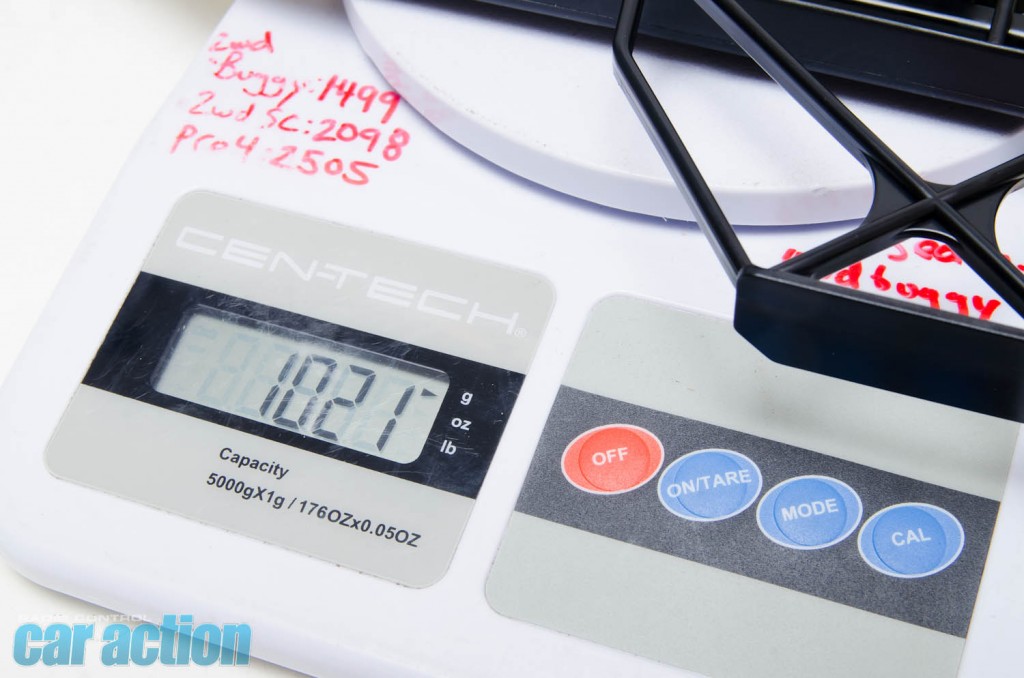

A top tier truck like the SC6 deserves electronics of the same caliber. I plan to install an Orion power package that includes their new Vortex R10.1 speed control, 8.5T VST2 Pro Brushless Motor and Orion Carbon Pro 4000 WTS.

Keep an eye out for my full review of the SC6 in the November issue of RC Car Action.

Sources

Kyosho kyoshoamerica.com

The post Kyosho Ultima SC6 Online Build appeared first on RC Car Action.