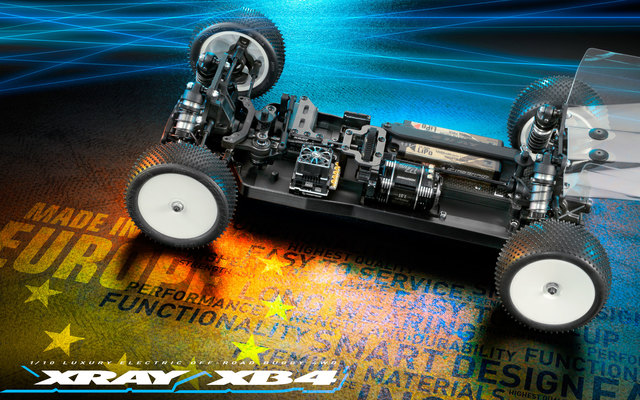

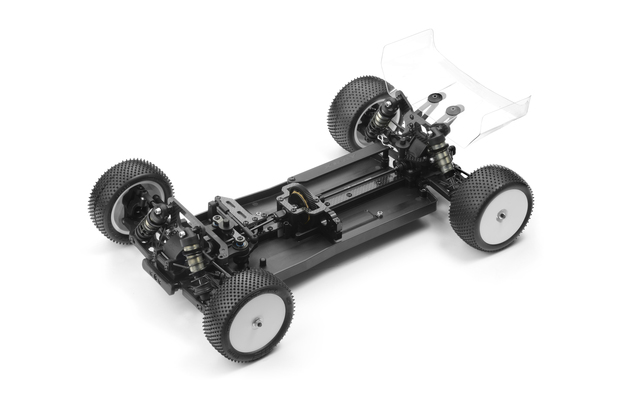

XRAY XB4 2020 4WD Buggy

From XRAY:

2020 All-new Features:

- All-new longer chassis for improved stability

- All-new super-narrow front & rear gear boxes to accommodate new suspension mount positions and optional longer arms

- All-new rear gear box height adjustment plate for high traction conditions

- All-new narrow front & rear suspension holders

- All-new front & rear gear differentials with increased oil volume to improve consistency

- All-new differential crown gear

- All-new steel crown gear and pinion gear CNC-machined from Hudy Spring Steel with improved lifespan and reduced noise

- New center drive shafts feature 2.5mm drive shaft pins for increased efficiency

- All-new longer front and rear drive shafts

- Updated aluminum motor mount with easier pinion gear access

- All-new center upper graphite brace

- Updated aluminum roll center mount on rear uprights with new roll center position

- Shorter slipper assembly with wider adjustment range for both low and high traction conditions

- Revised rear graphite shock tower can be mounted from both sides of the gear box

- Reinforced servo saver stands for improved steering precision and a new shape for improved clearance

- Improved servo mount system to improve steering consistency in high traction conditions

Chassis.

The XB4’20 chassis was lengthened to increase stability, while maintaining the desired the chassis flex for the best balance of traction and steering. The chassis was also narrowed in the front and rear sections to create the clearance necessary for the new suspension holders and narrower geometry.

The chassis accommodates the lower motor mount and allows the motor to be placed lower in the chassis that improves the cornering speed and stability.

CNC-machined from high-quality Swiss 2mm 7075 T6 aluminum, the chassis is strategically machined in low-stress areas to make it as light as possible without affecting strength or rigidity; and it is additionally black-coated for increased lifespan.

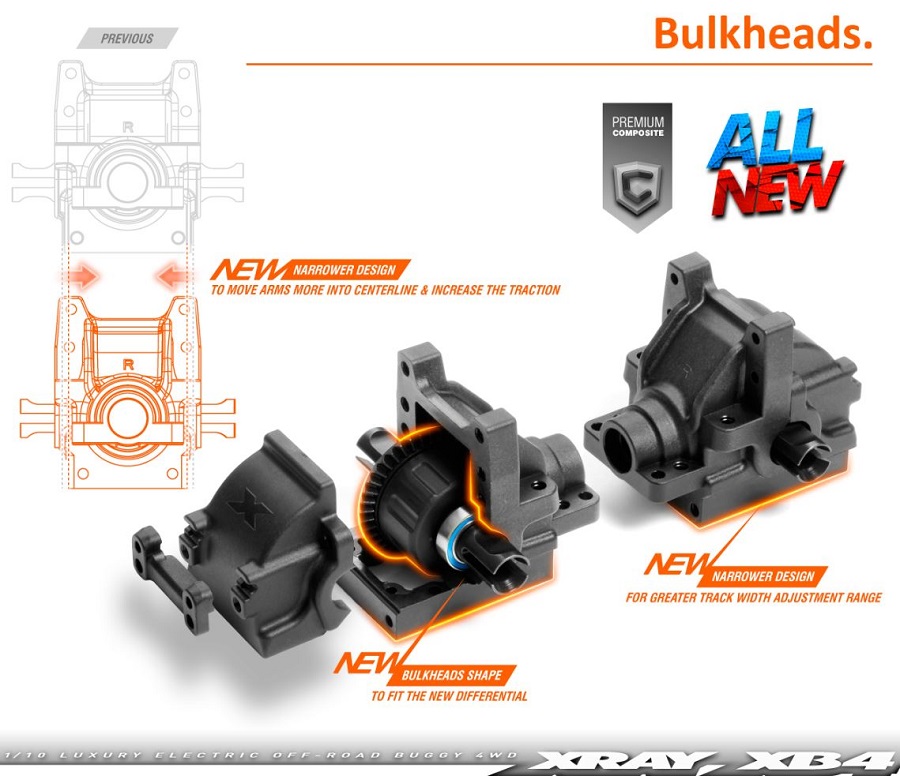

Bulkheads.

The all-new super-strong narrow bulkheads provide the needed clearance for the new narrow suspension holders on the XB4’20. This additional clearance allows for a wider range of track width adjustments and for moving the inner suspension pivot closer to the vehicle centerline. The new bulkheads have a perfect fit to the all-new front and rear differentials and are reinforced to increase their reliability.

The XB4 bulkheads allow super-fast & easy diff exchange and servicing by dismounting only 4 screws from the front of the bulkhead and bottom of the chassis. This super-fast diff access is available at both front & rear. The bulkheads have minimal ball-bearing play, resulting in increased gear teeth lifespan and minimized gear stripping.

Bulkhead Height Adjustment.

All-new graphite plate is used for the rear bulkhead height adjustment. Increasing height of the gear box makes the car more reactive in the high traction conditions and is suggested for use on carpet tracks.

For the low traction conditions, it is suggested to remove the graphite plate to place the bulkhead lower and thus generate more traction. Suggested for dirt tracks.

Gear Differential.

The all-new gear differential was completely redesigned both in front and rear, featuring a split design of the cover and crown gear. The differential case also has greater internal oil volume to increase consistency of the diff action, yet it is significantly narrower to fit into the new narrower bulkheads and to move the rotating weight closer to the centerline.

The super-smooth, low maintenance gear diff includes a composite case and cover with internal satellite gears that are precision-molded from special XRAY-developed graphite composite material, ensuring a long lifespan and super-smooth, efficient operation.

Gear differential features all-new diff-outdrives designed for use with 2.5mm pin.

Diff Gears.

The all-new split design of the gear differential features a separate lightweight crown gear and a separate diff cover. The split design results in significantly lower rotating mass and improves the serviceability.

The crown gear is now CNC-machined from HUDY Spring Steel and is ultra-hardened making it very strong and reliable with a longer life span. The split crown gear allows for a simpler exchange to optional gears without requiring a rebuild of the internal diff assembly.

To improve the gear engagement both crown gear and pinion gear have more teeth and new geometry that results in smoother engagement and increased efficiency.

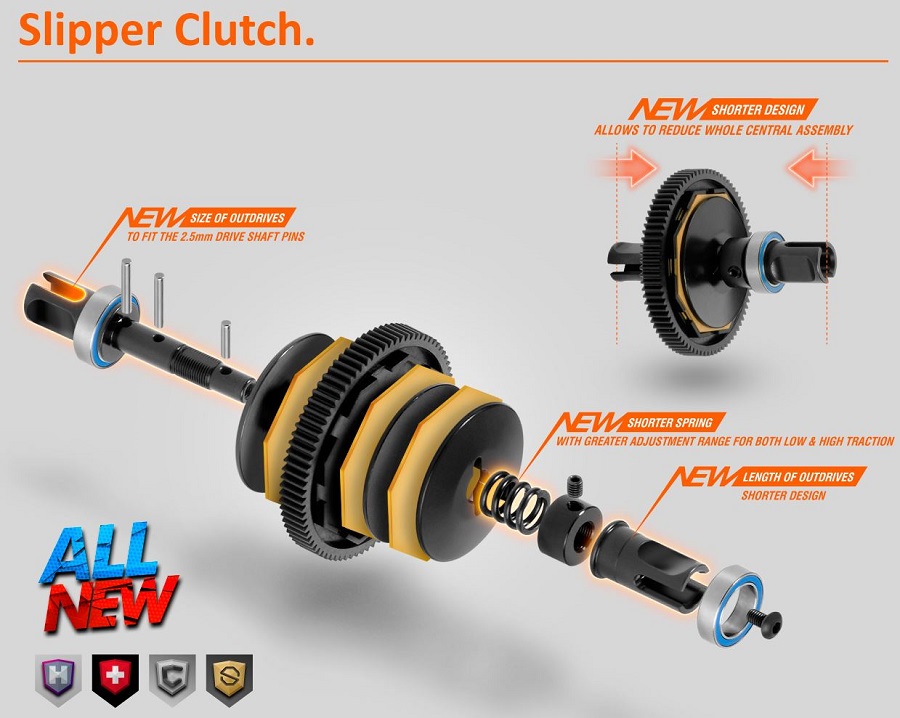

Slipper Clutch.

The all-new shorter slipper clutch reduces rotating mass and improves efficiency. The new slipper components shorten the entire central assembly to reduce weight yet still provide a greater adjustment range for both low and high traction conditions. Both outdrives are shorter and are also updated for the 2.5mm driveshaft pins now used throughout the XB4’20 drivetrain.

The adjustable 3-pad slipper clutch ensures smoother clutch operation and more efficient braking, and clutch adjustment is easier, more consistent, and ultra-fine. The lightweight slipper clutch plates have a machined relief which decreases the friction surface to assist with clutch slip adjustment.

The slipper clutch pads are made from ultra-efficient SLS material with very high slip efficiency. The clutch outdrives are super lightweight, manufactured from HUDY Spring Steel and additionally hardened for extra lifespan & reliability. The slipper plates are machined from premium Swiss 7075 T6 and additionally hardened, then given a black final surface treatment.

and additionally hardened for extra lifespan & reliability. The slipper plates are machined from premium Swiss 7075 T6 and additionally hardened, then given a black final surface treatment.

Central Differential.

The optional central differential was also completely redesigned. Using the same universal diff case and internal parts found in the new front/rear differentials, the central diff has greater internal oil volume to increase consistency of the diff action, yet at the same time it is significantly shorter than the previous version to fit the new narrower central assembly and to minimize rotating mass.

The maintenance-free super-smooth gear diff includes a composite case and cover with internal satellite gears that are precision-molded from special XRAY-developed graphite composite material, ensuring a long lifespan and super-smooth, efficient operation.

Gear differential features all-new diff-outdrives designed for use with 2.5mm pin. The gear diff set includes 81T spur gear and 78 and 84T spur gears are available as an option.

The central differential is recommended for use on clay, bumpy Astro and low-traction tracks to increase traction.

Diff Outdrive.

The diff outdrives were redesigned with a smaller design for the new front and rear differentials and the new narrower slipper clutch assembly. The center outdrives now feature the same 2.5mm pins used on the front and rear diffs.

To reduce rotating weight, the super-lightweight diff outdrives are machined from HUDY Spring Steel material which allows additional material to be removed on the outer part of the outdrives, further reducing the weight without effecting durability. The inner part of the outdrives is additionally hand-ground for perfect fitment into the diff case.

material which allows additional material to be removed on the outer part of the outdrives, further reducing the weight without effecting durability. The inner part of the outdrives is additionally hand-ground for perfect fitment into the diff case.

The outdrives are hardened using XRAY’s own special hardening process to provide extended lifespan and reliability.

Center Driveline.

Everything is new on the central driveline – drive shafts, motor mount, slipper clutch, drive gears, bevel gears. Everything is new, lighter and more compact for improved efficiency and reliability.

Drive Shafts.

The front and rear driveshaft lengths are updated to match the new differential width and suspension geometry; the front drive shaft is 83mm long and the rear drive shaft is 75mm long.

The safety collar on the front driveshaft secures the pin, while the ball bearing captures the pin in rear axles, both preventing the pin from coming lose during a run.

XB4 constant velocity drive shafts are manufactured from world-renowned HUDY Spring Steel and feature 2.5mm drive pins for maximum drivetrain efficiency. The drive shafts are some of the world‘s thinnest yet most durable drive shafts used in electric off-road cars. Hardened with a proprietary hardening process, the drive shafts provide unbeatable lifespan and reliability.

and feature 2.5mm drive pins for maximum drivetrain efficiency. The drive shafts are some of the world‘s thinnest yet most durable drive shafts used in electric off-road cars. Hardened with a proprietary hardening process, the drive shafts provide unbeatable lifespan and reliability.

Motor Mount.

The motor mounting plate features a new shape for easier access to the pinion gear set screw. The inner motor screw is now recessed into the mount for improved clearance around the center spur gear.

The motor is connected to an eccentric mounting plate, with the assembly then inserted into an integrated motor holder/drivetrain support. The design allows quick & easy motor rotation to adjust gear mesh, and still securely holds the motor plate using only a single screw.

To ensure the motor will not loosen in a serious crash or due to insufficient tightening, the motor plate has a bayonet mounting system which prevents it from being dislodged from the motor holder. By rotating the motor mount plate to the opposite direction, the motor can be quickly removed from the vehicle.

Removing the motor or adjusting the gear mesh is easy and fast, with changes possible in only a few seconds.

Central Bulkhead.

The central assembly features a new upper top deck to match new layout of the motor mount and central bulkheads on the chassis plate. The entire assembly is more compact with weight placed as close to the chassis centerline as possible. The new upper deck also fits the optional central differential’s new case design and dimensions.

The graphite central upper deck holds ball-bearings in the motor mount and bulkhead assembly, while the upper deck allows easy access for slipper clutch adjustment.

Rear Uprights.

The XB4’20 includes the updated roll center mounts for the rear uprights.

The upper roll center is adjusted at the camber linkage via shims (up/down & in/out), while the lower roll center is adjustable via eccentric inserts for 9 different positions (up/down & in/out).

The multi-function uprights have the upper roll center position in the middle of the axis of the driveshaft joint to help generate more traction and increase stability.

There are three different uprights available: hard (included), graphite (optional), and aluminum (optional), each suitable for particular track conditions.

Shock Towers.

The rear shock tower has a new design so it can be mounted in front or behind the rear bulkhead. The rearwards assembly put more weight on the rear with more downforce to the rear as well generating more rear traction, suggested for low traction tracks.

The optional rear aluminum shock tower features new three different wing mounting positions for improved adjustability.

Both front & rear shock towers are machined from premium-grade graphite and are lightweight & strong, with multiple shock positions and roll center adjustment positions.

I.S.S. Suspension Holders.

Suspension Holders.

All-new narrower suspension holders move the inner pivot location closer to the vehicle center allowing to use longer and shorter suspension arm alternatives and new suspension geometry. The narrower design increases rear traction.

The aluminum suspension holders feature Integrated Suspension Settings (I.S.S. ) which allows for quick & easy suspension geometry set-up.

) which allows for quick & easy suspension geometry set-up.

Machined from premium Swiss 7075 T6 aluminum and black coated.

Steering System.

The reinforced servo saver stands are now machined from one piece to simplify assembly and to improve steering precision, especially in high traction conditions.

The dual arm steering system is very simple yet effective and features an easily adjustable, integrated servo saver. Ackermann is easily adjusted by quickly changing the steering link mounting positions on the steering plate.

Bump steer is adjusted for more aggression by inserting a shim between the steering block and steering linkage.

Servo Mount.

The servo mount has a more compact and stronger design. The servo mount is now secured to the side guard to eliminate any unwanted servo movement that can occur in very high traction conditions. The reduced deflection translates into more consistent and precise steering response while cornering.

XRAY Instruction Manual.

XRAY Instruction Manuals have become the industry standard, being simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all the instructions are straight-forward and easy to understand. The full-color instruction manual contains large 3D illustrations that show all assembly details in the clearest possible way.

World Champions.

At the World’s most competitive off-road race – the IFMAR World Championship, it was XRAY’s Bruno Coelho and Daniel Kobbevik securing another World Champion and Junior Champion titles for the XB4 platform.

XRAY XB4 – the multi-time World Champion 1/10 off-road 4WD car that will bring you to the Winners’ Circle.

Visit TeamXRAY.com

See more posts about XRAY

Never miss an issue of RC Car Action!

Subscribe today with a Digital Edition subscription or Print + Digital combo!

The post XRAY XB4 2020 4WD Buggy appeared first on RC Car Action.